TakeOne®

Product Gallery

Information

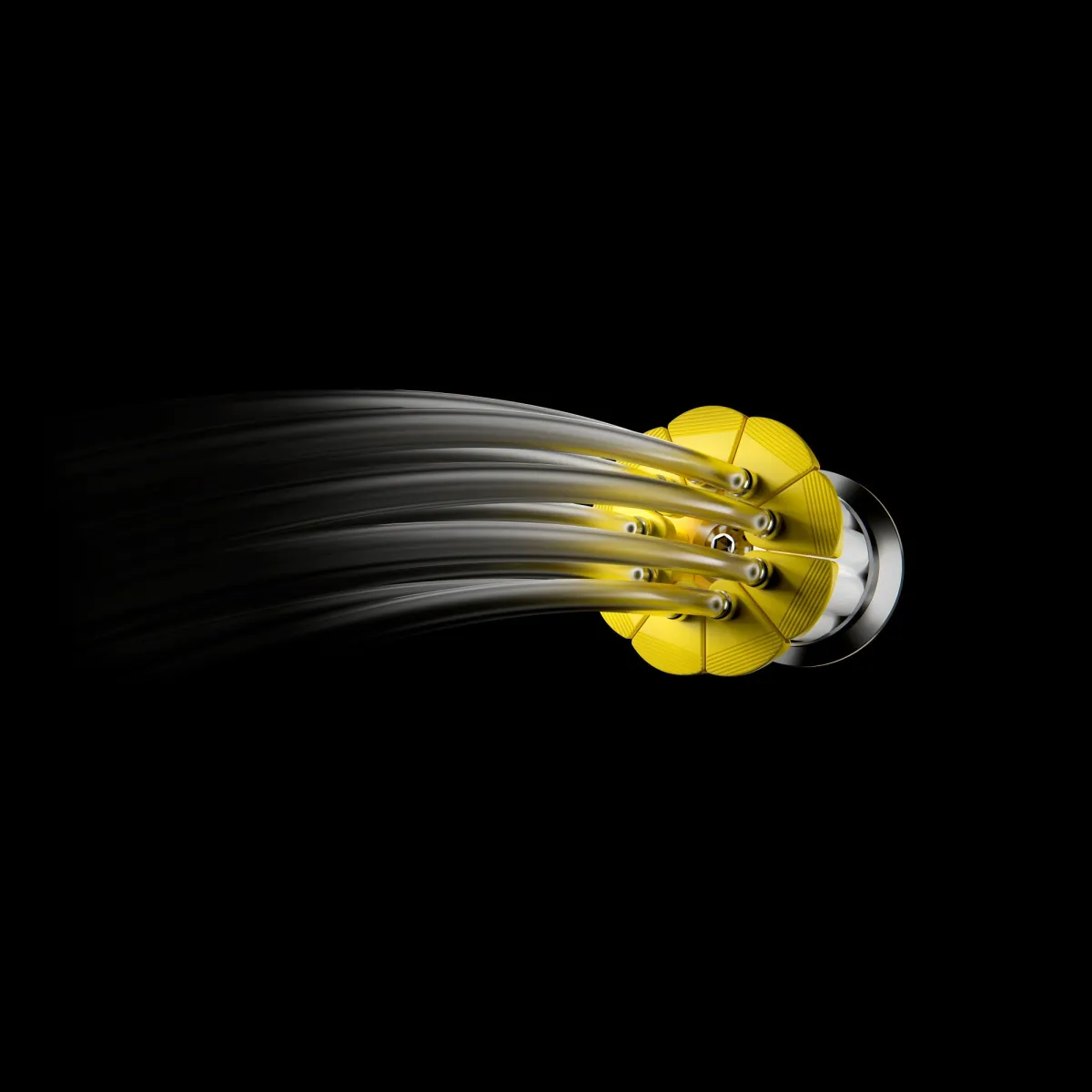

Preassembled, Presterilized, Single-Use: For Simplified Sampling

Aseptic sampling is a principal component of an effective microbial control program. Samples collected with TakeOne® are used to measure critical purity attributes, such as bioburden and endotoxin levels, as well as important process parameters, such as metabolites, nutrients, osmolality, pH and more. TakeOne® aseptic sampling solutions have been designed to integrate seamlessly to stainless steel biopharmaceutical containers and processes. TakeOne® is quick, accurate and reliable.

Reliable Solutions for Sample Collection or Fluid Transfer and Storage

Sartorius offers a complete line of solutions for sample collection or for transferring small volumes of fluids to storage. TakeOne® sampling solutions integrate with stainless steel and single- use applications and incorporate process enabling technologies and configurations that significantly expand sample taking capacity.

A broad range of collection containers includes bags in a variety of film materials, as well as bottles and tubes that feature our robust Mycap® aseptic bottle closures.

Country

Germany

Product Type

Sampling Device

Application Areas

* Upstream Processing * Downstream Processing * Process Containers * Single-Use Sampling * Pharma * Food & Beverage * High Accuracy Sampling

Key Features

Break Process Bottlenecks with TakeOne® Devices Engineered to take representative samples for accurate results with no risk of false positives for every process step. A closed system design ensures process fluids can easily be collected for analysis while protecting the process from adventitious agents. * Pre-assembled * Pre-sterilized * 100% integrity tested * Curated selection of collection containers for reliable, repeatable assay results Take the Complexity Out of Sample Planning and Small Volume Fluid Handing TakeOne® and Mycap® offer a wide range of container formats, volumes and fluid contact materials so you can select the right container for your application. Optimal container selection is be based on a variety of factors like: process step, sample analysis type, assay sensitivities, material compatibility, fluid value, handling preferences and volume. Proper selection can improve the accuracy of test results while decreasing cost per sample and lost product. Contact us for more detailed information on the booth 3F73.