Continuous Drug Product

Products

Information

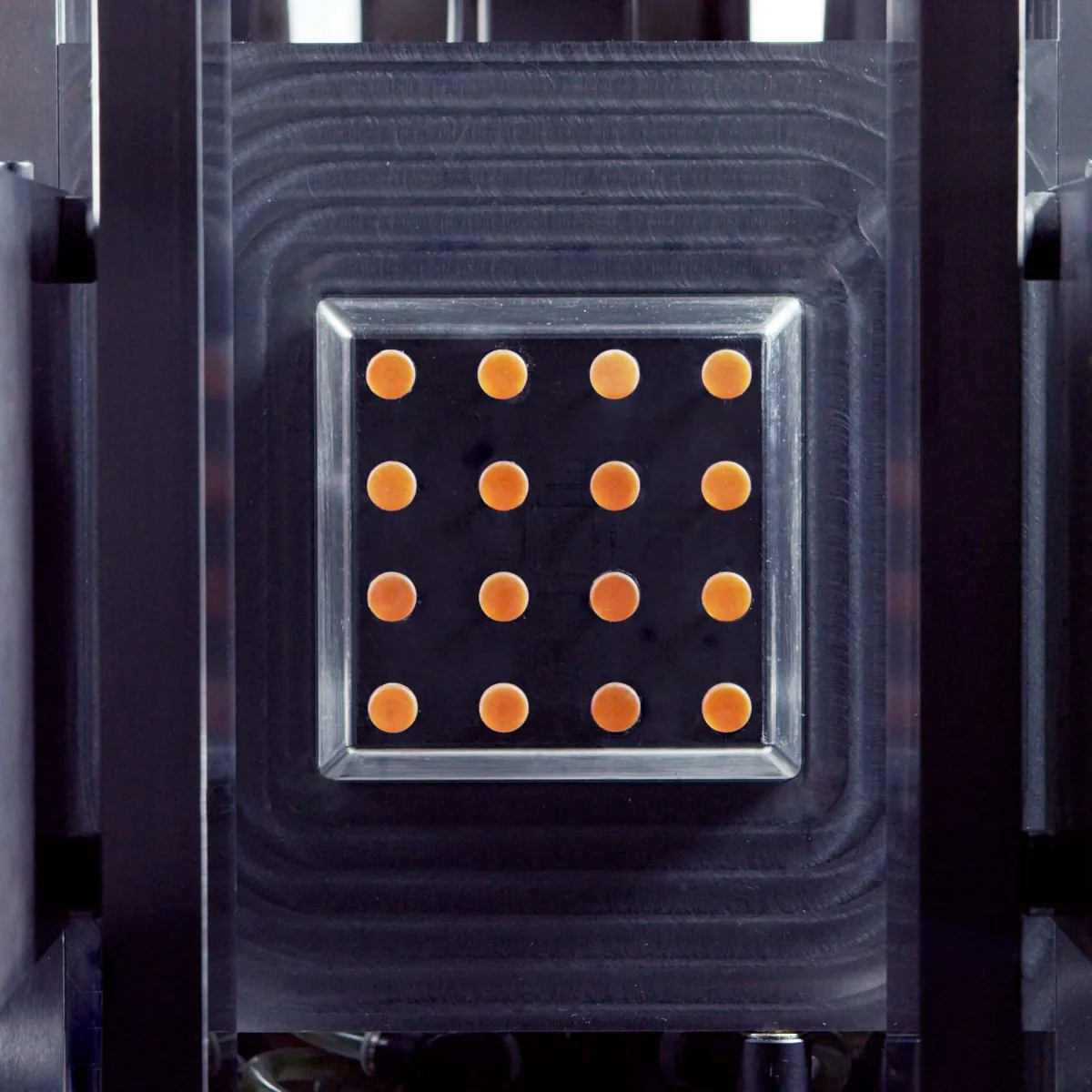

Our proprietary Integrated Extrusion-Molding process produces pharmaceutical-grade coated tablets in a continuous fashion. The drug substance is conveyed from the upstream continuous dryer to the loss-in-weight feeder dedicated to the API, which is placed above the twin-screw extruder of the EM unit and in front of the loss-in-weight feeder intended for the excipients. The excipients gravimetric feeder is continuously filled with a pre-blended mixture of different excipients suitable for the final drug product quality attributes and process. Then both feeders continuously deliver the API and excipients in the correct API/excipient ratio to reach the desired drug load. The powders are gradually processed by the extruder, which mixes the materials and applies shear under high temperature and pressure. The resulting homogeneous extrudate flows through the transfer manifold, which is the integration point between the extruder unit and the core injection unit. The transfer manifold is equipped with two optical grade windows, each one with its own adaptor and port, where PAT probes are installed. Then the extruded material enters the core injection unit with a specific process control algorithm. The core injection unit accumulates the material shot and then injects it into the mold cavities. The cavities, designed per the tablet's shape and size requirements, are cooled down with a cooling agent that allows hardening of the molten formulation into the desired tablet shape. After the tablets are cooled and hardened, they are ejected and collected.