HYDRA: Keeping Production Flowing, Even When Units Fail

Featured Products

Information

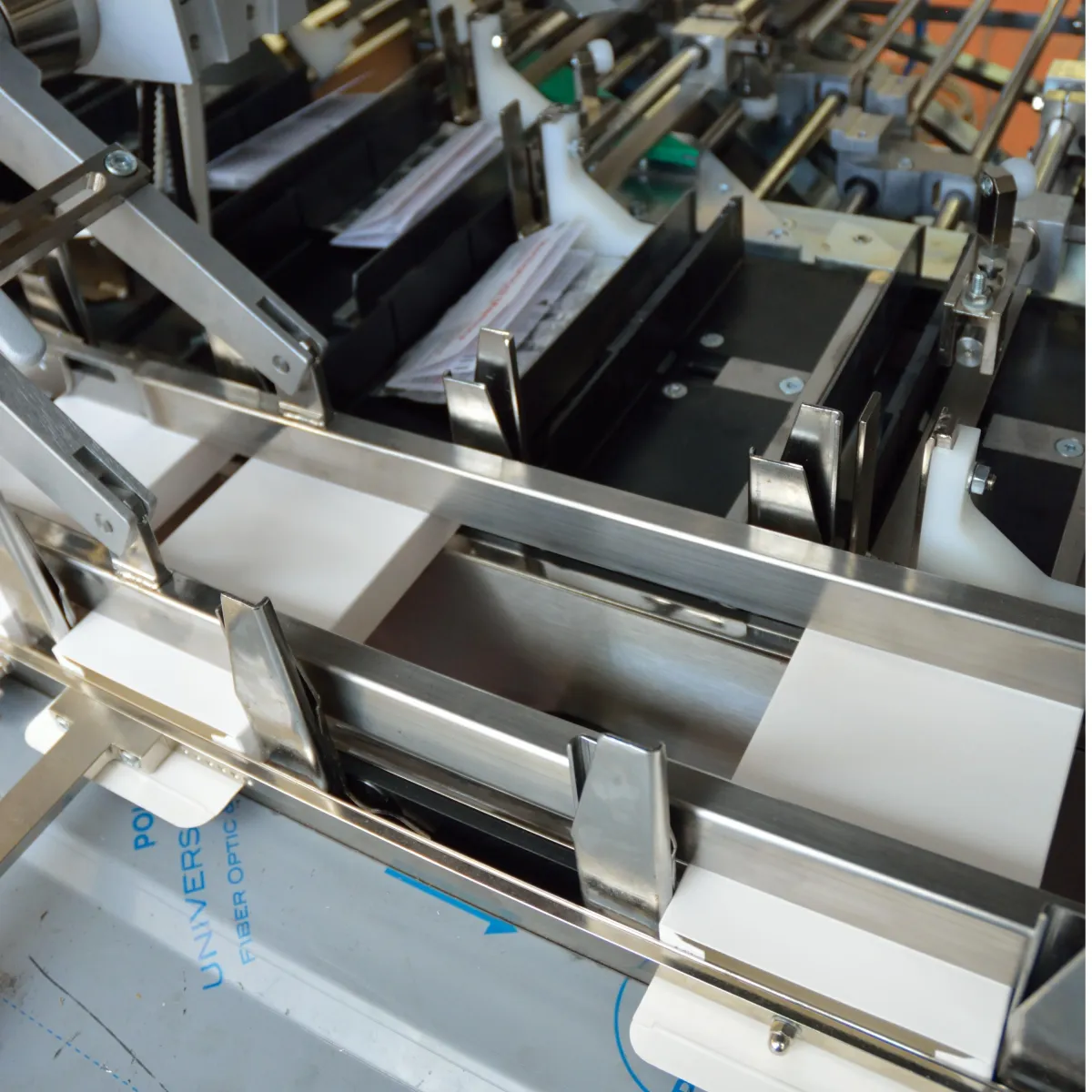

THE HYDRA SYSTEM PREVENTS PRODUCTION INTERRUPTIONS CAUSED BY FAULTY OR INEFFICIENT UNITS. The system is compatible with all packaging machines. For example, on a continuous cartoner, multiple units insert bottles, spoons, and leaflets into cartons. If any unit fails or malfunctions, the HYDRA system keeps production running if other stations can perform the same function, minimizing downtime. HYDRA uses sensors and statistical software to detect damaged stations and automatically controls the product infeed, preventing items from entering faulty sections. If a station fails—such as a gripper arm—the system blocks product pick-up for that area without halting overall production. HYDRA operates in three modes: AUTOMATIC: The system monitors stops, analyzes statistics, and suggests disabling problematic stations, notifying maintenance staff. SEMIAUTOMATIC: Operators remove faulty stations, and the system disables related feeders so removed parts are excluded from operation. MANUAL By means of a dedicated page on the operator panel, the operator can select the faulty station and the sys¬tem will not enable the product feeder. In this way, the faulty station will never be used in the production operations.